- Product description

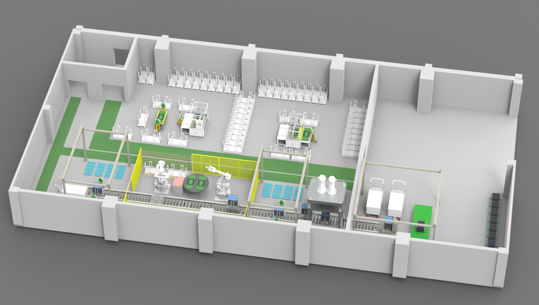

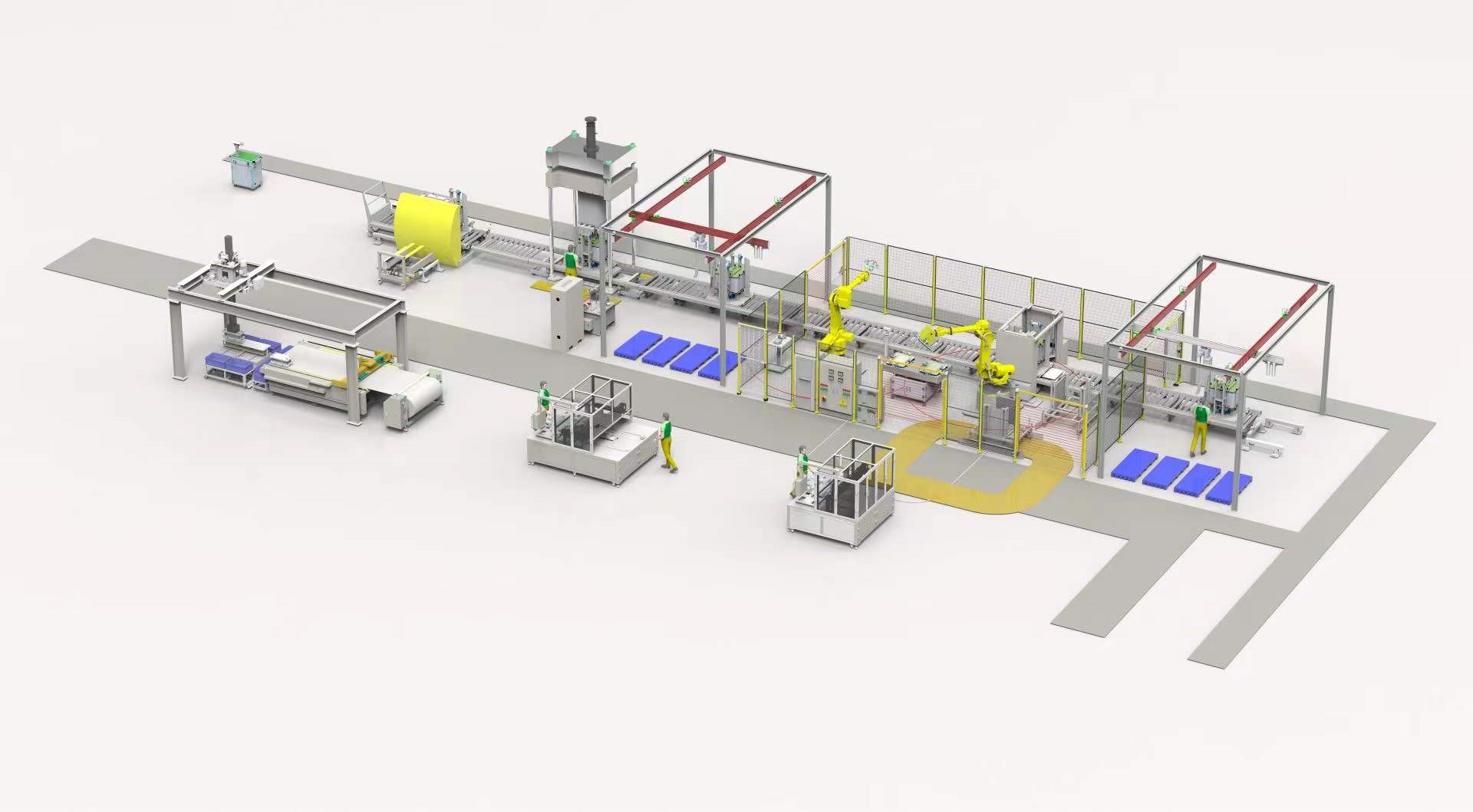

u it can realize full-automatic continuous production of feeding, double plate bonding, sealing ring forming and blanking, and the qualification rate of primary process equipment is ≥ 98%;

u dispensing can ensure that there are no defects such as lack of glue, broken glue and overflow, and high-precision camera is configured to detect the dispensing effect;

u double plate bonding can ensure reliable sealing of water channel and no coolant leakage;

u the forming of the sealing ring can ensure the reliable sealing of the gas flow channel and no leakage of reaction gas;

u sealing ring molding can be divided into dispensing and glue injection processes, which can be selected according to customer needs;

u the production line is equipped with high-precision robots and visual inspection to ensure the consistency of product quality;

u the production line is equipped with MES system, which can remotely monitor production and realize quality traceability;

u the production line can be linked with AGV material vehicle to realize intelligent and unmanned production;

u can customize the development according to the special needs of customers to meet the needs of customers in terms of process, capacity and automation.