- Product description

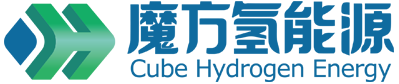

u it can realize full-automatic continuous production of feeding, stacking, pressing, fastening and blanking, and the qualification rate of primary process equipment is ≥ 98%;

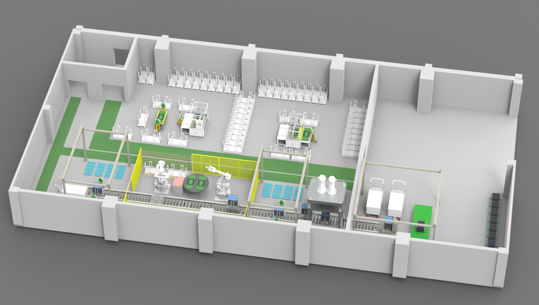

u imported high-precision robots and supporting suction cups are adopted to automatically absorb stacked materials;

u stacking tooling positioning mechanism is used for accurate positioning. The robot grabs the stacked materials and CCD visual secondary fine positioning, with positioning accuracy of ± 0.1mm, and identifies the positive and negative of materials to prevent misplacement;

u the system counts the stacking of materials and sets the number of different stacking layers to meet different production needs

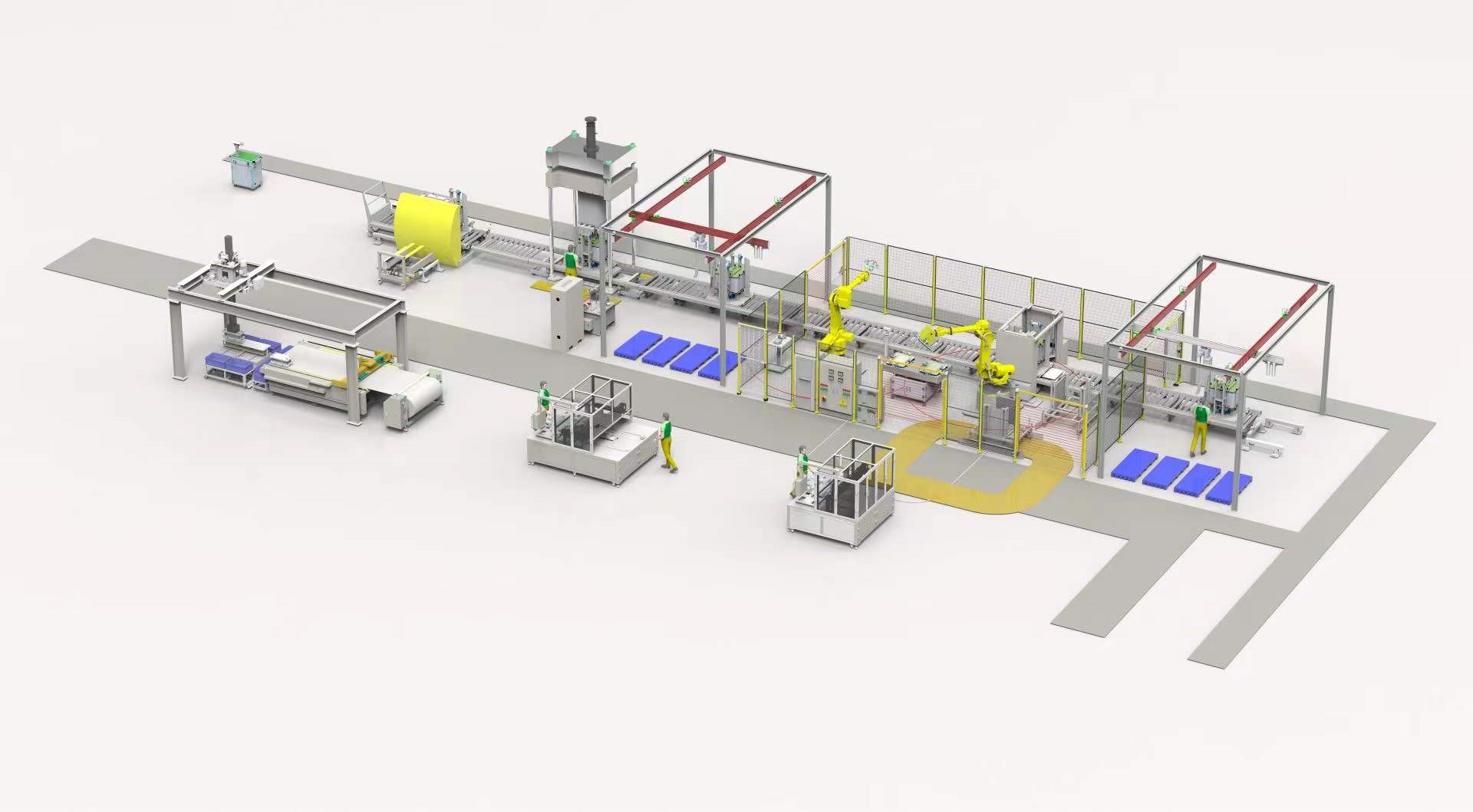

u pressure at different points can be monitored and pressure mode or stroke mode can be set during press fitting;

u press stroke accuracy ± 0.02mm, press accuracy grade 0.2% FS;

u fastening can be divided into screw, tie and side plate, which can be selected according to the customer's process;

uThe U press is integrated with an on-line air tightness detection system, which can automatically detect the air tightness after fastening;

u set up an independent ng station to deal with the abnormal conditions in the process of stacking to ensure the continuity of production;

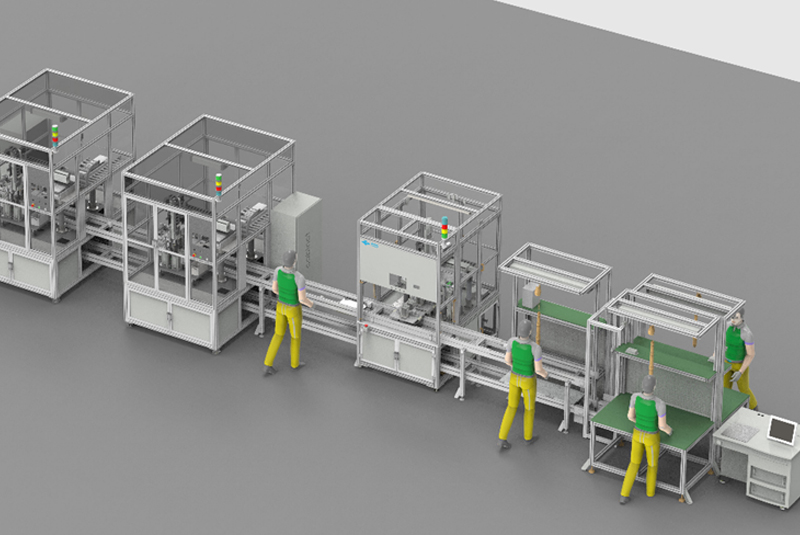

u the whole line is equipped with MES system, which can remotely monitor the production, and the supporting code scanning system can upload and bind the production data in real time, and carry out quality traceability;

u the whole line can be equipped with AGV automatic material distribution vehicle to realize intelligent and unmanned production;

u it can be customized and developed according to the special needs of customers to meet the needs of customers in terms of process, capacity and automation